管材檢測系統(tǒng)MultiScan MS5800系列 這是一款可利用渦流、漏磁、遠(yuǎn)場及IRIS超聲技術(shù)的多技術(shù)檢測系統(tǒng)。 The MultiScan MS5800 is a multi-technology system offering these technologies: Eddy Current Magnetic Flux Leakage Remote Field IRIS Ultrasound

這是一款可利用渦流、漏磁、遠(yuǎn)場及IRIS超聲技術(shù)的多技術(shù)檢測系統(tǒng)。

The MultiScan MS5800 is a multi-technology system offering these technologies:

Eddy Current

Magnetic Flux Leakage

Remote Field

IRIS Ultrasound

Tube Inspection with Eddy Current Testing (ECT)

Tube Inspection with Internal Rotating Inspection System (IRIS) for Ferrous and Nonferrous Materials

Tube Inspection with Remote Field Testing (RFT)

Tube Inspection with Near Field Testing (NFT)

Tube Inspection with Magnetic Flux Leakage (MFL)

MS 5800E

Tube Inspection with Eddy Current Testing (ECT)

Condensers

Condensers  Eddy current testing is a noncontact method used to inspect nonferromagnetic tubing. This technique is suitable for detecting and sizing metal discontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks in nonferrous materials.

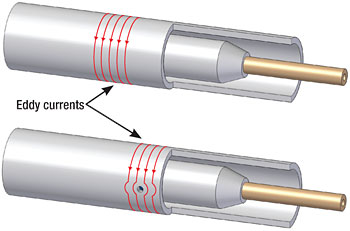

Eddy current testing is a noncontact method used to inspect nonferromagnetic tubing. This technique is suitable for detecting and sizing metal discontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks in nonferrous materials. Two coils are excited with an electrical current, producing a magnetic field around them. The magnetic fields penetrate the tube material and generate opposing alternating currents in the material. These currents are called eddy currents.

Two coils are excited with an electrical current, producing a magnetic field around them. The magnetic fields penetrate the tube material and generate opposing alternating currents in the material. These currents are called eddy currents.  Boilers

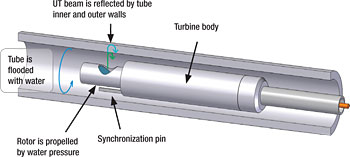

Boilers  The ultrasonic IRIS option is used to inspect a wide range of materials, including ferrous, nonferrous, and nonmetallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts. Olympus digital IRIS inspection technology is used extensively as a prove-up technique for remote field testing, magnetic flux leakage, and eddy current inspections.

The ultrasonic IRIS option is used to inspect a wide range of materials, including ferrous, nonferrous, and nonmetallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts. Olympus digital IRIS inspection technology is used extensively as a prove-up technique for remote field testing, magnetic flux leakage, and eddy current inspections. MultiScan MS 5800U (IRIS) Key Features

MultiScan MS 5800U (IRIS) Key Features Boilers

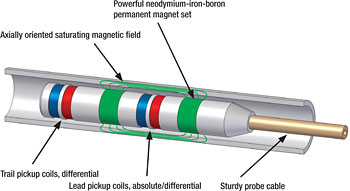

Boilers  Remote field testing (RFT) is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferritic stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts.

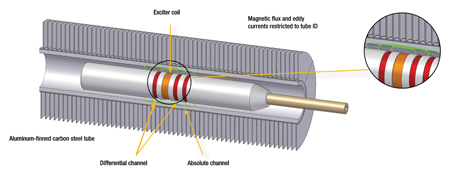

Remote field testing (RFT) is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferritic stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts. Near field testing (NFT) technology is a rapid and inexpensive solution intended specifically for fin-fan carbon-steel tubing inspection. This new technology relies on a simple driver-pickup eddy current probe design providing very simple signal analysis.

Near field testing (NFT) technology is a rapid and inexpensive solution intended specifically for fin-fan carbon-steel tubing inspection. This new technology relies on a simple driver-pickup eddy current probe design providing very simple signal analysis. Magnetic flux leakage (MFL) is a fast inspection technique, suitable for measuring wall loss and detecting sharp defects such as pitting, grooving, and circumferential cracks. MFL is effective for aluminum-finned carbon steel tubes, because the magnetic field is almost completely unaffected by the presence of such fins.

Magnetic flux leakage (MFL) is a fast inspection technique, suitable for measuring wall loss and detecting sharp defects such as pitting, grooving, and circumferential cracks. MFL is effective for aluminum-finned carbon steel tubes, because the magnetic field is almost completely unaffected by the presence of such fins. The array technologies are highly valuable when high resolution or imagery is desired. The MultiView acquisition and analysis software features improved C-scan functionality for easy setup and analysis in a virtually unlimited number of layouts.

The array technologies are highly valuable when high resolution or imagery is desired. The MultiView acquisition and analysis software features improved C-scan functionality for easy setup and analysis in a virtually unlimited number of layouts. Each MS5800 is currently delivered with the acclaimed Backpack (20ED0074, U8764077), which provides your operational staff with maximum comfort and protection. The Backpack, which was developed and tested in the field with the assistance of several service companies, also provides additional space to carry calibration tubes, probes, or adaptors.

Each MS5800 is currently delivered with the acclaimed Backpack (20ED0074, U8764077), which provides your operational staff with maximum comfort and protection. The Backpack, which was developed and tested in the field with the assistance of several service companies, also provides additional space to carry calibration tubes, probes, or adaptors.

The optional MS5800 Footswitch (TA-FSW-001, U8770248) provides productivity gains to individuals or two-person crews when recording data. With its field-proven, rugged design, it enables the operator to remotely perform the majority of common operations by programming several useful and configurable functionalities in the MultiView software, without the need to directly access the computer.

The optional MS5800 Footswitch (TA-FSW-001, U8770248) provides productivity gains to individuals or two-person crews when recording data. With its field-proven, rugged design, it enables the operator to remotely perform the majority of common operations by programming several useful and configurable functionalities in the MultiView software, without the need to directly access the computer.